OR-UPIT

Specifications

- Microprocessor controlled

- 7” touch screen panel

- Ethernet, USB, Flash drive connection and LabLogic+ PC Software

- Graphical and Tabular result profiles and statistical analysis

- Conforms to ISO 13802

- Up to 50J testing energies for Izod, Charpy, Tensile Impact and Component testing

- Conforms to ISO and ASTM Testing methods ASTM D256 and 6110, ISO 179 and 180, ISO 8256 method A (specimen in bed)

- Test results units in KJ/M, KJ/M² and FT/LBs force

- Variable Velocity to 3.8 m/s (12.47 ft/sec) with Electro magnet pendulum release

- 1k PPR digital rotary encoder

- Self calibrating for Frictional losses and windage

- Electro magnetic pendulum brake

- Fully Interlocked enclosure and 2 button pendulum release for operator safety.

- Fully traceable certificate of calibration and instrument user manual

- UKCA/CE Certified

- Dimension (CM) - 110W x 52D x 78H

- Net Weight (Kg) - 145

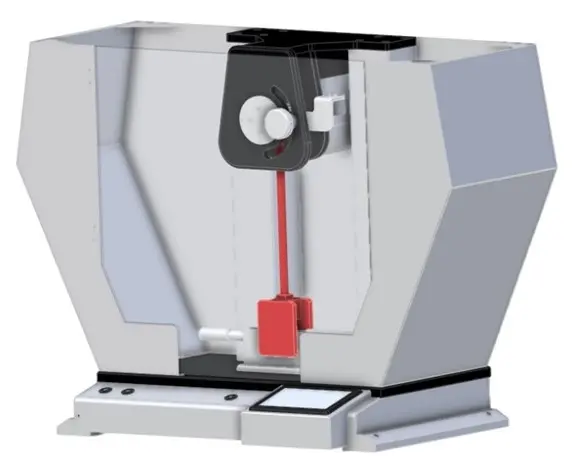

Universal Pendulum Impact Tester

Introducing a brand new range of materials testing equipment from Orion-PTS.

The Orion-PTS Universal Pendulum Impact Tester has been designed in accordance with ISO13802 to determine the energy required to break test specimens processed from plastics, composites, ceramics and non ferrous metallic materials to International testing methods for Izod, Charpy, Tensile Impact testing and Component testing, including small pipe sections and should more than meet your growing demand for accurate and precise testing to ASTM and ISO testing methods for resin manufacturers, polymer processors, construction, automotive and aerospace industries.

The instruments ease of operation and high accuracy makes it ideal for QA/QC within Production, Research and Development labs and Teaching Institutions. Impact velocities are variable up to 3.8 m/s covering testing methods ASTM D256 (Izod), ASTM D6110 (Charpy), ISO179 (Charpy), ISO180 (Izod) and ISO8256 (Tensile Impact). Highly accurate variable weight and single piece impact pendulums are available up to 50J capacity which are released by an electro magnet. Impact energies are calculated using a 1k PPR optical rotary encoder which records the lost angle of rise after impacting a test sample against the angle of rise recorded from the pendulums initial calibration procedure at a given velocity, taking into account friction and windage. The resulting lost angle is calculated as the test sample’s Impact Energy in KJ/M, KJ/M² or ft-lbs/in, ft-lbs/in².

Test setup is simple by entering data on the 7” touch screen panel which provides simple on screen instructions. Test parameters such as operator names, material reference codes and batch codes are entered and stored in lists for test result presentation and future test result recall. Test type and testing parameters such as impact hammer weight, impact velocity and sample dimensions are entered to give the required testing conditions. For QA/QC purposes high and low limits can easily be set allowing the user to instantly assess if the material under test is a pass or fail.

Test results are recorded and displayed after each test and downloaded into Orions LabLogic+ software either by USB, Ethernet or direct download to USB flashdrive for import into LabLogic+. Batch statistics of mean, standard deviation and co-efficient of variation are automatically updated after each test and results are shown in graphical and tabular format for analysis and reporting. Sample break types are also captured as Full, Partial, Hinged and Non-break and detailed on the test report.

The instrument is supplied complete with fully interlocked enclosure and dual button pendulum release for user safety as well as a pendulum brake, The instrument conforms to ISO13802, ASTM D256, ASTM D6110, ISO179, ISO180, ISO8256 method A amongst others.

The apparatus is supplied multi voltage 110-240v 50/60 Hz.

Options

- Izod, Charpy, Tensile Impact Fixtures

- Component Fixtures to customers specific requirement

- Izod, Charpy and Tensile Impact Pendulums to 50J