OR-COF

Specifications

- Microprocessor controlled

- 7” touch screen panel

- Ethernet, USB & flash drive connection

- LabLogic+ download Software

- 1kg (10N) load cell fitted as standard

- Variable test speeds up to 1600mm/min

- Variable test travel distance up to 350mm

- Calculations for Static and Dynamic (kinetic) COF values. μ & grams

- Servo motor control

- User definable sample dwell period

- Graphical test results.

- Sample cutting template

- Supplied complete with ASTM od ISO 200g test sled and load cell calibration kit

- Fully traceable certificate of calibration and instrument user manual

- UKCA/CE Certified

- Dimension (CM) - 65W x 40D x 20H

- Net Weight (Kg) - 20

Options

- Heated Bed

- Vacuum Bed

- Test sled with adjustable mass (no greater than load cell capacity).

- “Fishtail effect” stabilizer

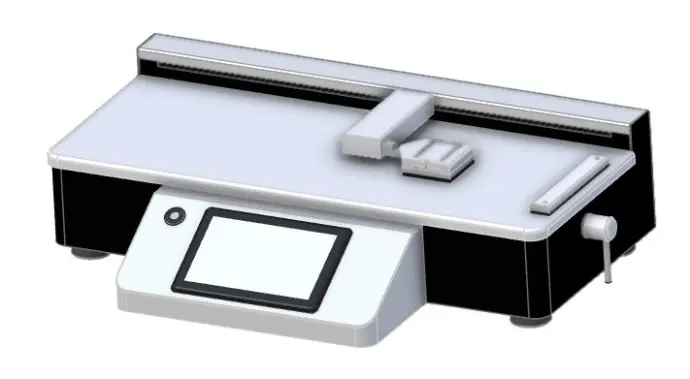

Co-efficient of Friction Tester

Introducing a brand new range of materials testing equipment from Orion-PTS.

The Co-efficient of Friction Tester is one of the most widely used instruments in the quality control of polymer films within the flexible packaging and coatings industries and has been designed to meet ASTM D1894 and ISO 8295 international Testing Standards to understand the “Slip” properties of materials that impact the production process of polymer films or frictional properties coatings have on base materials.

A dedicated flat bed (horizontal) test instrument, Static and Dynamic (kinetic) coefficient of friction properties of materials are calculated using specified test conditions such as test sled weight, test velocity and temperature making this apparatus ideal for all types of flexible packaging, foils, paper, board, rubber, laminates and textiles for R&D laboratories or QA/QC validation and verification. Repeatable test results for co-efficient values with normal separating loads less than 1 kef are easily determined using the standard test sled or specific peel attachments. Complimented with a 7” touch screen panel, test setup is simple and can be configured for test speed, test distance, test temperature (optional heated bed required), test sled weight and sled dwell time.

During the test procedure the static friction value is taken at the precise moment that movement occurs then dynamic (kinetic or sliding) friction is immediately observed and recorded graphically. To measure this peak friction value, the on-board microprocessor continually monitors the output signals of the load cell. Load cell readings are taken beyond the peak static load in order to confirm that the slope of the load curve is reducing. When the static frictional value has been determined by the microprocessor the dynamic friction is measured during the selected travel distance. The result given is the average of these readings. However, by displaying the results graphically on a computer, each of the

readings can be inspected to examine any variation in the test results over the selected travel distance. High and low test values can be input for internal QA/QC and multi-slicing values give real time graph analysis and tabular results of the material under test so no physical cutting of the material needs to be done, and Stored Test Parameters can easily be recalled from memory for easy test setup.

Supplied as standard with a 200g test sled to either the ASTM or ISO test standard, calibration kit and Orion's LabLogic+ software for reporting. Connectivity to PC is via USB or Ether-net or direct download to USB flash drive so test results can be opened in LabLogic+. The apparatus is available with a heated bed for sample testing at elevated temperatures or vacuum bed option to ensure material lies flat to the test bed. Other options are available for 90deg and 180 deg peel testing for pressure sensitive tapes.

The machine is multi voltage as standard 110v—240v 50/60hz but configured to correct country voltage if heated bed option is fitted.